Materials Testing

Materials testing plays a critical role in various industries to ensure that the materials used meet the specified requirements and have the desired properties. For metallic materials in particular, permeability, ferrite content and magnetic flux are of paramount importance. These parameters have a significant influence on the magnetic properties of materials and are therefore essential for applications in electrical engineering, mechanical engineering and other technical fields.

Modern testing methods play a crucial role in the accurate determination of these parameters. Technological advances, such as non-destructive testing methods, make it possible to test materials for their magnetic properties without compromising their integrity.

Contents (hide)

1. Magnet Permeability

Low permeability materials such as stainless steel have a lower magnetic permeability than high permeability materials. This has several interesting effects and applications:

Low Magnetizability: They are less easily magnetized than high permeability materials. This fact influences the application possibilities in circuits and electromagnetic components.

Applications: Non-magnetizability is of great importance in medical technology, particularly in the manufacture of surgical instruments and medical devices that use magnetic resonance imaging (MRI).

2. Ferrite Content

Careful control of ferrite content is necessary to ensure desired material properties.

The ferrite content of steels, especially austenitic stainless steels, plays a critical role in welding technology. Ferrite is a body-centered cubic lattice structure and is a magnetic phase in such steels. An appropriate ferrite content is important to ensure the mechanical, corrosive and welding properties of the welded material.

During welding, the material is affected by heat. Uncontrolled heat influence can change the ferrite content and lead to undesirable microstructures. It is therefore important to monitor and control the influence of heat during the welding process.

Too low a ferrite content (ferrite deficiency) or too high a ferrite content (ferrite excess) can affect the mechanical properties and corrosion resistance of the welded material.

Ferrite content directly affects the mechanical properties of the welded material, including tensile strength, hardness, and ductility.

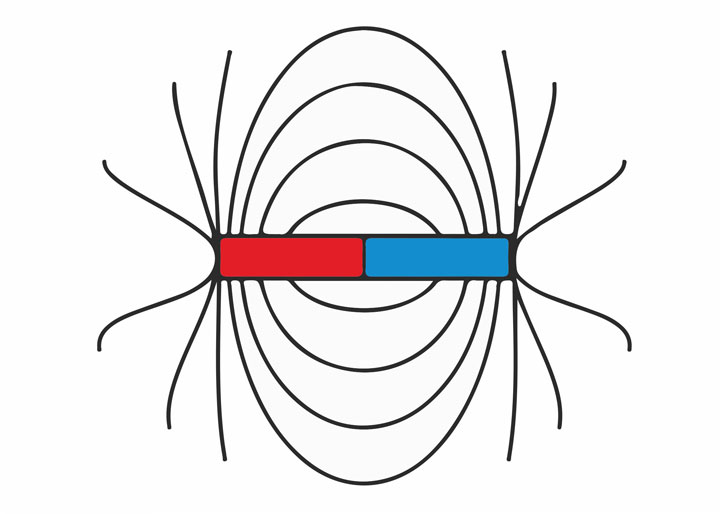

3. Magnetic Flux

A fluxmeter is an instrument used to measure the flow of magnetic flux density, also known as magnetic flux, in a material. It plays an important role in various applications, particularly in materials testing, electrical engineering and magnetometry.

Accurate measurement of magnetic flux is critical in the design and testing of electromagnetic components such as transformers, coils, and inductors.

In manufacturing, a fluxmeter can be used to ensure that workpieces achieve the required magnetic properties during the magnetization process. This is particularly important in industries such as automotive and electrical appliance manufacturing.

A fluxmeter can also be used to detect defects or irregularities in magnetic components or materials. Flux variations can indicate problems such as cracks or uneven magnetization.

In scientific research projects, especially in materials science and magnetism research, a fluxmeter is used to characterize new materials and understand their magnetic properties.